Ishlanma Tizimlari-da Yuqori Struktural Koʻrsatmalar

Ogir Yuklar uchun Ogirlikka Nisbatan Yuqori Kuch

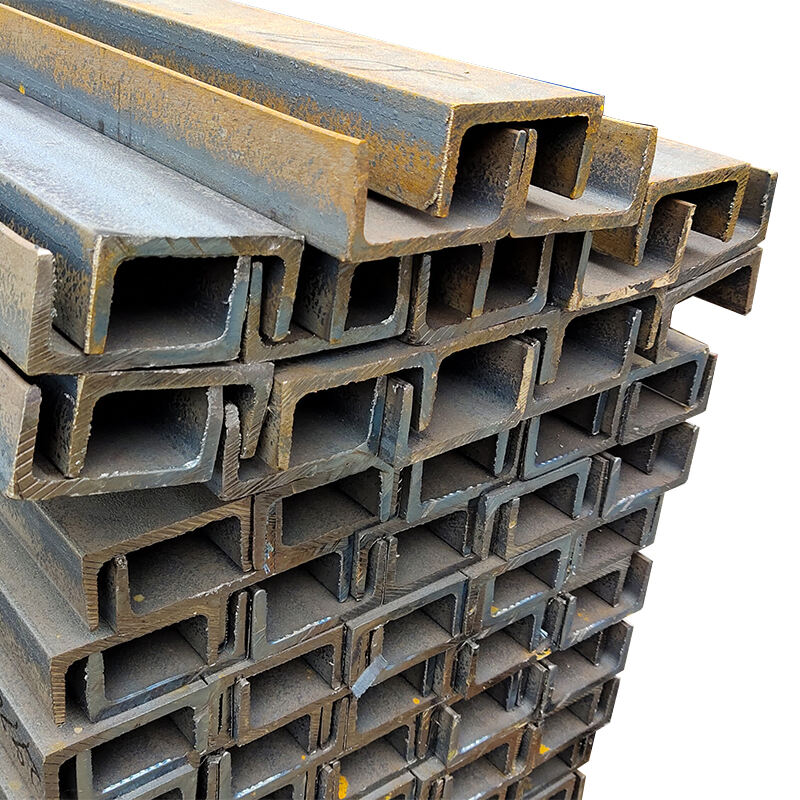

Kanal ploski o'zi og'ir yukni birlashtirish uchun eng ko'p ishlatiladigan burchakli metall dan og'irlikga nisbatan kuchli hisoblanadi. Maxsus qurilmasi materiallardagi yig'ilishni saqlash orqali xavfsizlik va ishonchdan tashqari faqatgina foydalanuvchi uchun ham foydali bo'ladi. Katta masshtabdagi qurilmalarda bu maxsus qurilma aluminium allowance yoki ba'zi stainless telleridan ko'ra ko'proq qo'llanma mavjud. Issledovchilar tomonidan tasdiqlanganidek, unda ko'proq yukni boshqarish imkoniyati bor va shuning uchun bu material bino konstruksiyalari uchun eng yaxshi tanlov hisoblanadi.

-

Afzalliklar kanal Metallining Og'ir Yuklar Uchun Foydasi

- Kuchlilik : Ko'proq alternativ materiallarni takrorlaydi.

- Material effektivligi : Xavfsizlikni saqlashda kamroq material talab qiladi.

- Xavfsizlik : Yukni birlashtirish uchun ishonchli hisoblanadi.

O'tkazmacha va Engellarga Qarshi Kuch

Kanal metallining geometrik shakli uni o'ngirilish va burilish yuklariga qarshi ko'tarish quvvatini yuqori sathda saqlashga imkon beradi, bu esa binolarda kuchni yengil saqlash va loyihani xarajatini pasaytirishga yordam beradi. Katta hajmdagi tijoratgi qurilmalarga ushbu xususiyat zarur bo'ladi, chunki stabillik va shakl saqlash asosiydir. Inzheneriyaviy tadqiqotlar namunacha, oddiy va murakkab holatlarda kanal metalli 6061 aluminiy alloydan yaxshiroq performans ko'rsatadi. Ular arxitektura imkoniyatlari uchun muhim xususiyatlarni birlashtiradi, masalan, qarshilik va moslashuvchanlikni.

-

Sabablari bor Kanal Metall Struktural Boshqaruvda Yutqazib O'tmaydi

- Yuqori Darajadagi Burilish Qarshilik Quvvati : Struktural shaklni va stabilniyatni saqlaydi.

- E'tirodli Yuk Bilan Ishlashda Muvaffaqiyat : Bosim ostida butunlikni saqlaydi.

- Sharq Tarmoqlari Shartlarda Ko'proq Performans : Inzheneriyaviy tadqiqotlar va sinovlar orqali isbotlangan.

Qurilish loyihalari bo'yicha ko'pfunksional ravishda qo'llanilishi

Tijoratgi Qurilmalardagi Divor Ramkalari va Dam Stoyoklari

Mavjud quruv kanali kommersiy ishlariga o'xshash yana bir kichik nimoya sifatida yetib kelmoqda; xususan to'r va qalay ko'rsatkichlarda. Uning xos robu'ti va davomiyligi loyihalar uchun turli xil muammolarni hal qilishga imkon beradi. Shuningdek, quruv joyida transport va hisob-kitobda qulay ravishda olib ketilganda, kanal poyasi og'ir emas, shuning uchun bu yerda ko'p vaqt va ish xarajatlari tekinlik bilan saqlanadi. Bu yerda, yetarlicha muhim foydani ajratadigan narsa, ishlab chiqarish jarayonida baland darajadagi aniqlikdir, bu ishlab chiqarish davomida kamroq atrof mahsulot borligini anglatadi, shuning uchun kanal poyasi narxlari nisbatan past, bu materiallardagi ishlab chiqarishni boshqarishga harakat qilayotgan uy quruvchilariga foydali bo'ladi.

Prefabricatsiya va modullarli quruv bilan integratsiya

9) Kanal qattiq aqlli precast va modullar konstruksiyasi bilan integratsiya uchun qulay, masraf va ish kuchini saqlaydi. Kanal qattiqni prefabricatsion tizimlarda ishlatish faqat oson va tez tuzilishi mumkin, balki oxirgi konstruksiya doimiy ravishda stabillik ko'rsatadi. Sanoatda kanal qattiqning istalgan modullar yig'indisi uchun tezroq davom etish orasidagi bog'liqlikga oid xabarlarning chiqqaniga to'g'ri keladi, bu esa raqamli loyiha yetkazib berish darajalarining oshishi orqali isbotlangan, shuningdek, loyihaning sifati uchun shunga qaramay, muddatlar shiddat bilan bajarilishi kerak.

Uzoq muddatli ilojiylik va korrozziya oldovchanligi

Namli muhitlarda Aluminium alloydan yaxshi performans

kanal ploski metall aluminium allowslari bilan solishtirilganda, masalan 6061 aluminium uchun, xususan namlikli havo atmosferasida korrozziyaga qarshi ishlatilishi orqali yaxshi natija beradi. Issledovchilar o'rtacha namlik etkisi kanal ploskani asl holatini va vizual ko'rinishini zor korroziv elementlarga nisbatan uzun vaqt davom etishiga sabab bo'ladi. Ushbu material turli qiyinchiliklar to'plami quyoshli, sanoat va namli hududlarda qurilish uchun ideal hisoblanadi, chunki bunday shartlar qiyin bo'lgan holda bino elementlarini buzib tashlay oladi. Shuningdek, kanal ploskasining tabiiy uzun muddatli holati bino strukturalarining hayoti uzaytiradi va ularning umumiy xizmatlash narxini pasaytiradi.

Noxo'q metall uchun himoyaviy to'pishlar - darajali himoya

Muhojja qandaylik bilan, kanalning korroziasizligi rustli to'qim sochqalarining bilan bir xil. Ushbu to'qimlar to'qimni muhit elementlari tomonidan sabablanadigan ziyonadan himoyalash orqali uni hayotini uzaytirishda foydali. Maydon surveylari isbot qiladi, muhojja qilingan U-kanali uning muhojjasiz holatdan ancha ko'proq davom etadi va vaqt o'tishiga nisbatan kamrasmul tuzatish talab qilinadi. Bunday to'qimlarni ishlatganda, kanal to'qimi turli muhitlarga qo'llanilishi mumkin va bu yerda ishlatilganda loyihalar davriy ranglangan holda yoki eskirgan masalalaridan qochish uchun butunlik va shakllarini keng tarqatilgan davomida saqlay oladi. Bu texnologik yangiliklardan foydalanish konstruksiya mutaxassislari uchun boshlang'ich investitsiyani va davom etuvchi xarajatlarni kamaytirishda effektiv hisoblanadi.

Nafaqat material, balki o'rnatishda ham qimmat emas

Soddalashtirilgan jamlash orqali ish kuchining xarajatini pasaytirish

Kanallik qalincha kesish, suvlayish va mashinalashga oson bo'ladi, bu esa uning qurilish maqsadlarida ishlatilishi uchun ideal yechim bo'lishini ta'minlaydi. Narxiy tufayli foydasi, o'rnatish uchun talab qilinadigan ish miqdori kamayishi sababli bo'ladi, chunki kanallik qalincha qismlarini bog'lash uchun maxsus asboblar va ko'nikmalar talab qilmaydi. Masalan, ko'plab tashkilotlar kanallik qalinchani ishlatganda bir necha loyihaning turida ish haqi va vaqti 20% gacha kamayishi haqida hisob-kitob beradi. Bu kattaroq ta'sirli saqlantirishlarga olib kelishi mumkin va shuning uchun kanallik qalincha pulini eng yaxshiliqda ishlatmoqchi bo'lgan kompaniyalar uchun istalgan yechimdir.

Loyiha hayot muddati boyicha kasr xizmat

Kanal ploski metallining qo'l qilish quvvati loyihaning hayoti davomida xarajatlarini pasaytirish va effektiv iqtisadi foydani oshirishning muhim komponentidir. Issledovchilar o'rtasida kanal ploskasi bilan loyihalar, boshqa materiallardan tashkil topgan teng qiymatdagi loyihalarga nisbatan uzun muddatli xarajatlarda pastroqdir. Ushbu pastroq saqlash talablari bino egasi va operatorlari uchun vaqt davomida pulni saqlash juda katta foyda hisoblanadi. Kanal ploskasining davomiyligi va qiymati Kanal ploskasi quruv bo'yicha uzun muddatli vazifani bajardi, uni saqlash, iqtisadiy va kuchli foydasi orqali.

Davomiyligi bo'yicha quruv foydalaridan

Miktarlangan alternativlarga nisbatan qayta ishlash imkoniyati

Kanal ploski - bu ekologik maydonida qayta ishlash mumkin bo'lgan biologik asosdagi materialdir, chunki u ko'p boshqa kompozit materiallardan farqli ravishda qayta ishlash mumkin. Kombinirovannye materiallar oxirgi ishlangan holda olib tashlashda muammolar bilan urinib chiqadi. Kanal ploski ning qayta ishlashining ekologik ta'sirini kamaytirishda katta ahamiyati bor va qabarga yotkazishdan va ba'zi konstruksiya - yetkazib berish jarayonidan kelib chiqadi. Ushbu xossalar ekologik ravishda o'ylab chiqqan quruvchilar uchun mashhur tanlovi hisoblanadi, chunki u sifat kaybini eng kam darajada qoldirgan holatda qayta ishlab chiqarilishi mumkin. O'yin sohasida eng muhim ma'lumotlar oxirgi yillarda ayday olgan tendentsiya: qurilish loyihasi kanal ploskilari to'g'ri ro'yxatdan o'tkazilgan materiallardan iborat. Bu ushbu sayrni yakunlaydi va yangi resurslarning talabini kamaytiradi, shuning uchun davom etuvchi qurilish tsikli yaratiladi.

Ishlab chiqarish va transportdagi energiya effektivligi

Yashil ishlab chiqarish va transport channel metalli uning loyiha karbon izini kamaytirish funksiyasini belgilaydi. Ba'zi qurilish materiallari ularni ishlab chiqarish uchun ko'p energiya talab qilishi bilan bir xil emas, channel metallining yaratilish usuli maksimal energiya saqlash uchun muvaffaqiyatli hisoblanadi. Ular mahalliy ta'minotchilar bilan ishlash orqali transport emissiyalarini kamaytirishadi, shuningdek ekologik foydani oshiradi. Hayotiyya baholashlariga ko'ra, channel metall umuman boshqa materiallardan yuqori ishlab chiqarish va transport uchun past energiya sarflashini anglatadi, bu qurilish dizayni yo'ldoshlikka oid eng ilmiy usuldir. Bu kam tarqalgan ishlab chiqaruvchilar hamda jahon miqdoridagi davomiylik muhimligini stress beradi - materiallarni hayot davri foydalariga qarab tanlash.

Mundarija

-

Ishlanma Tizimlari-da Yuqori Struktural Koʻrsatmalar

- Ogir Yuklar uchun Ogirlikka Nisbatan Yuqori Kuch

- O'tkazmacha va Engellarga Qarshi Kuch

- Qurilish loyihalari bo'yicha ko'pfunksional ravishda qo'llanilishi

- Tijoratgi Qurilmalardagi Divor Ramkalari va Dam Stoyoklari

- Prefabricatsiya va modullarli quruv bilan integratsiya

- Uzoq muddatli ilojiylik va korrozziya oldovchanligi

- Namli muhitlarda Aluminium alloydan yaxshi performans

- Noxo'q metall uchun himoyaviy to'pishlar - darajali himoya

- Nafaqat material, balki o'rnatishda ham qimmat emas

- Soddalashtirilgan jamlash orqali ish kuchining xarajatini pasaytirish

- Loyiha hayot muddati boyicha kasr xizmat

- Davomiyligi bo'yicha quruv foydalaridan

- Miktarlangan alternativlarga nisbatan qayta ishlash imkoniyati

- Ishlab chiqarish va transportdagi energiya effektivligi